Surface Preparation

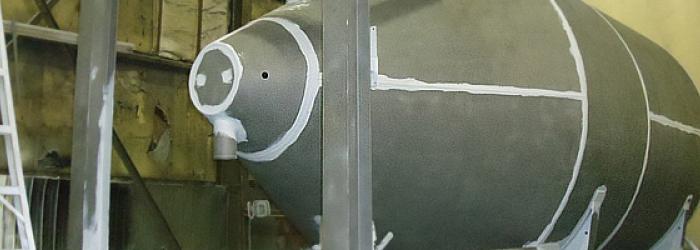

Sand Blasting

AML Painting has supplied abrasive blasting, industrial coating, and lining services in Atlantic Canada since 1990. At AML Painting, we are committed to quality and customer service. Our technicians are always upgrading their skills for safety, surface preparation and coatings application procedures. We are proud of our workmanship and strive to surpass our customers' expectations, from small jobs to large-scale contracts. Whether on your site or in our shop facilities, the experienced crews and custom blasting/painting equipment at AML Painting are ready to meet any of your protective coating and lining needs.

Water Blasting

For more than 24 years, AML Painting has been a leader in commercial/ industrial water blasting services across Atlantic Canada. We have extensive experience in all different types of commercial and industrial water blasting.

Shot Blasting

AML Painting utilizes Portable Abrasive Vacuum Blasting Equipment. More commonly recognized as Shot Blasting. This will clean your concretes surfaces without acids, chemicals, or sandblasting and without releasing dust or unsafe contaminants into the air. Moreover, since our equipment is portable and light-weight, we can start work with very little set up or preparation time. Vacuum Blasting System works just as its name implies. First, it scours the concrete surface with a powerful cleaning abrasive, and then it recovers and holds the contaminants in its own storage hopper. That makes this system the ideal way to remove dirt, old paint, thick coating, epoxy, polyurethane sealers and other surface coating and prepares the surfaces for the new applications without messy dust clean-up potential harmful chemicals or costly drying times. Shot blasting leaves your concrete clean, chemical free and ready for whatever floor covering you have selected to install.

Diamond Grinding

Grinding of concrete flooring is one of the most environmentally friendly preparation methods. At AML Painting grinders are used along side shotblasting for edging along walls and equipment. In the last decades the improvements in grinders have allowed for the use of large walk behind grinders for concrete preparation in addition removal of coatings and sealers. Depending on diamond sizes it can produce a very smooth uniform appearance. It is even possible to produce an almost marble or terrazzo-like appearance by using successively finer and finer abrasives to polish concrete. The hand grinding equipment works of standard grinder most commonly 7" models specially adapted with dust shrouds allowing them to be connected to dust recovery vacs. The walk behind grinders typically use several counter rotating blades and larger pulse vacuum systems.